We love to see 3M’s DI-NOC carbon fiber vinyl being used outside of just the automotive world. Things like prototyping, architectural design, technology, refinishing products, and more. The applications for the vinyl are literally unlimited. In the below video we guide you through the steps to wrap a refridgerator in the vinyl, giving it a completely different look than before. While the fridge we used already looked new, imagine taking one that is starting to look outdated, but works just fine. Using the vinyl, you can give it life once again and save money while giving it an updated look.\r\n\r\n

\r\n\r\nIf you have anything unique that you’ve used 3M’s DI-NOC for, let us know! We’re always looking for the latest and greatest uses.

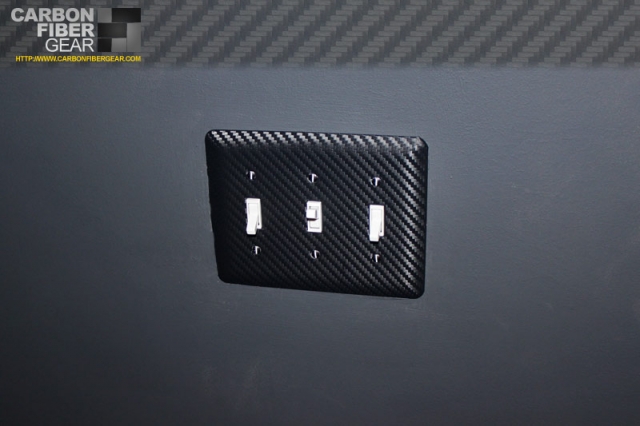

\r\n\r\nYou can see a few samples on the right-hand side of the above picture, here’s a closer shot followed by an explanation of the differences:\r\n\r\n

\r\n\r\nYou can see a few samples on the right-hand side of the above picture, here’s a closer shot followed by an explanation of the differences:\r\n\r\n \r\n\r\n

\r\n\r\n \r\n\r\nAs you can see, the piece on the left is DI-NOC as it comes with no clear coat. The other two pieces were clear-coated, the middle has just one coat, while the right piece has three coats. The pictures make it hard to show how it really looks in person because it’s highly dependent on the lighting. You’ll need to take a look at the video below for a better idea. We also tried doing another with five or six coats, but it starts to get a bit blotchy and fills into the texture.\r\n\r\nWe only tested on these sample pieces so we’re not sure how it will hold up over time or once installed. Upon inspection it seems like it would be just fine. With the three coats it starts to bend back a little (although it’s still bendable without issues), I would suggest clearcoating once the material is installed rather than before. This may seem obvious, but I just want to make that apparent. Make sure and mask off any areas prior to spraying that you don’t want cleared.\r\n\r\nFor spraying techniques take a look at the below video:\r\n\r\n

\r\n\r\nAs you can see, the piece on the left is DI-NOC as it comes with no clear coat. The other two pieces were clear-coated, the middle has just one coat, while the right piece has three coats. The pictures make it hard to show how it really looks in person because it’s highly dependent on the lighting. You’ll need to take a look at the video below for a better idea. We also tried doing another with five or six coats, but it starts to get a bit blotchy and fills into the texture.\r\n\r\nWe only tested on these sample pieces so we’re not sure how it will hold up over time or once installed. Upon inspection it seems like it would be just fine. With the three coats it starts to bend back a little (although it’s still bendable without issues), I would suggest clearcoating once the material is installed rather than before. This may seem obvious, but I just want to make that apparent. Make sure and mask off any areas prior to spraying that you don’t want cleared.\r\n\r\nFor spraying techniques take a look at the below video:\r\n\r\n